In our divisions, there are complex processes in which one wheel engages the other. A single person can not comprehensively survey that, a computer already.

By learning to understand the workflows and processes using mathematical models, he is able to plan them as efficiently as possible, with the effect of reducing costs and conserving resources.

So it can be said clearly that the use of a “digitized data collection” can make a major contribution to sustainability in the economy. Large companies are already taking this route, but especially SMEs (small and medium-sized enterprises) still have a lot of work to do.

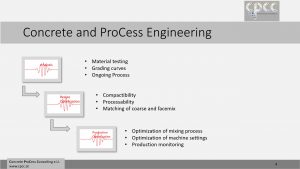

What CPCC offers for innovative concrete plants:

Networking:

Machines, devices, sensors and people can network with each other

Information transparency:

Sensor data expand information systems of digital factory models to create a virtual image of the real world

Technical Assistance

Assistance systems support people with the help of aggregated, visualized and understandable information. This enables sound decisions to be made and any problems that arise to be resolved faster. In addition, people are physically supported in strenuous, unpleasant or dangerous work.

Concrete ProCess Consulting e.U. can work out interesting solutions for you!

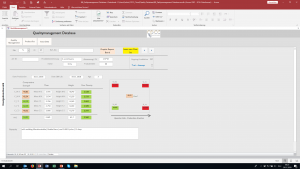

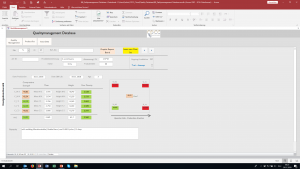

Over the years, technically professional software solutions for production, quality management and technical controlling have been developed to meet these needs and confirmed in practical applications.

This transparency not only adjusted and optimized organizational processes, but also saved enormous production costs.

Take the opportunity and contact them directly.

Excerpt from the CPCC lecture ICCX, Warsaw 13-15.2.2019